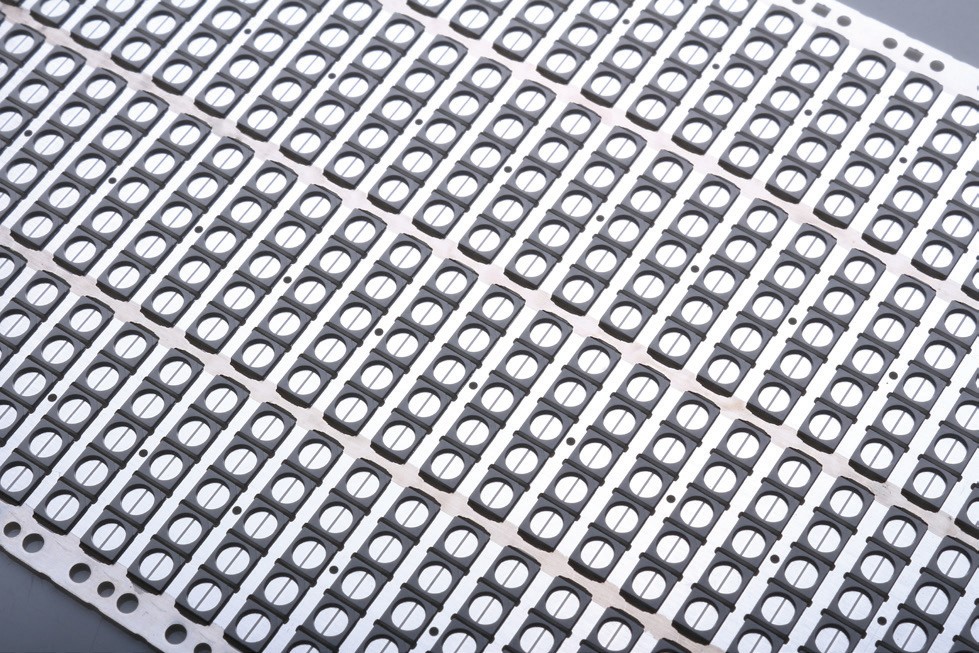

Transfer molding parts

ttop corp. has been dedicated to the LED lead frame manufacturing process for many years, delivering high-precision, high-yield, and cost-effective lead frame products. Our products are widely applied in LED packaging across various fields including general lighting, back light for display , automotive, sensors, and consumer electronics. Our core advantages are as follows:

1. Expertise in LED Lead Frames

With years of experience in the LED packaging industry, we are well-versed in the technical requirements of various thermosetting types such as EMC, SMC.

We respond quickly to industry trends toward miniaturization, high-power output, and enhanced thermal performance.

2. High-Precision Stamping Technology

Utilizing high-speed stamping presses and precise tooling technology, we achieve ultra-tight tolerances and stable product quality.

Multi-row continuous stamping boosts both production capacity and efficiency.

3. Consistent Surface Finishing and Plating Quality

We offer a range of surface treatments including full Ag plating, selective Ag plating, and Ni-Pd-AU (Ni-Au) plating to enhance conductivity and solderability.

Plating thickness and uniformity are strictly controlled to ensure consistent packaging performance.

4. Flexible Material Capabilities

We process a variety of materials such as C194 , C19210 , brass, phosphor bronze, and specialty alloys.

Dual-Gauge material stamping is also supported to meet the needs of LED product designs.

5. Strong Customization Capabilities

We provide rapid prototyping and in-house tooling design to shorten time-to-market for new products (NPI).

Custom lead frame design recommendations can be provided based on customer drawings or specific packaging requirements.

6. Comprehensive Quality Assurance and Certifications

Certified to ISO 9001, IATF 16949, and ISO 14001.

Complete in-process quality control is implemented, including Automated Optical Inspection (AOI) and precise dimensional measurement systems.

7. Fast Lead Time and Stable Supply Chain

With fully integrated in-house tooling, production, and plating processes, we ensure short lead times.

We have a proven track record of stable supply to major LED packaging manufacturers and international brands.

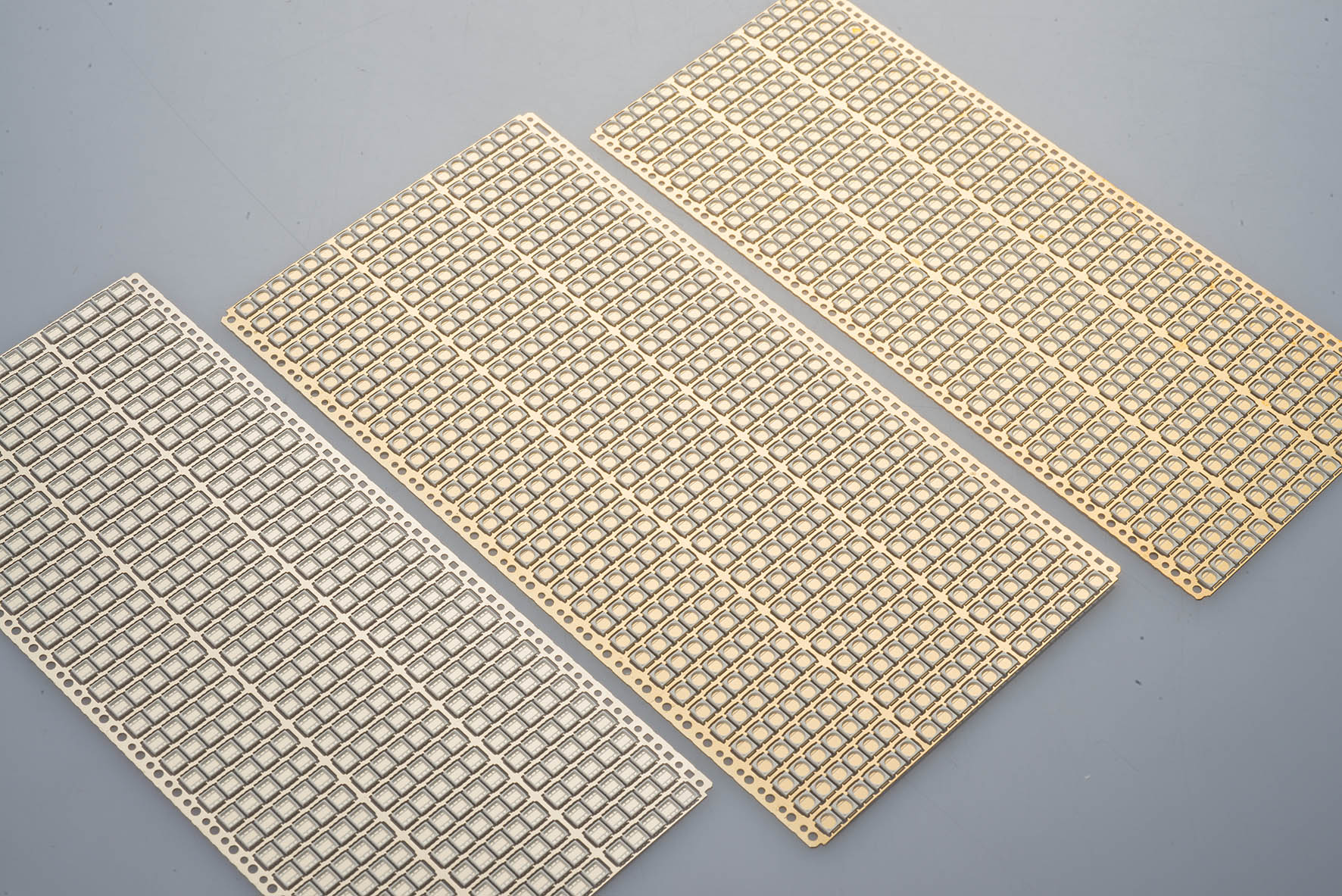

Raw material coil

Stamping

(Full/Partial) Electroplating

Strip Cutting

Transfer molding

De-Runner

De-Flash

Trimming , forming & Cutting

AOI, visual inspection & packaging