Company Introduction

ttop Corp. is located in the Quanxing Industrial Zone of Changhua County, Taiwan, with a factory area covering 1,264 ping (approximately 4,176 square meters). The company is certified with IATF 16949:2016, ISO 9001:2015 Quality Management System, and ISO 14001:2015 Environmental Management System.

ttop corp. has many comprehensive and modern production and measurement facilities, we are offers a total solution one-stop service—from product design, mold design , Mold build-up, Mold maintenance , stamping, electroplating, insert-molding, Transfer-molding,de-flashing, Trim & Forming process, and more.

Since its establishment, ttop corp. has specialized in providing precision stamped parts and injection molded parts, focusing on lead frames for SMD-LEDs, semiconductors, and heat sinks. ttop corp. is 1st to build-up the most cavities insert-mold to produce SMD LED Lead Frame in Taiwan. It also has holds numerous product patents.

ttop corp. has complete process technology capabilities, combined with automated production systems and strict quality control system, to provide our customers with stable and reliable products and fast delivery capabilities.

ttop corp. adheres to the business philosophy of "quality, innovation, sustainability" and will continue to invest in mold design and manufacturing, equipment automation upgrades, and green processes to enhance product competitiveness, reduce manufacturing costs, and comply with international environmental trends.

-

Company Namettop corp.

-

ttopThe top teams of tooling technology in Taiwan

-

Date of establishmentFebruary 2007

-

Paid-in capitalNT$267,300,000

-

Company AddressNo. 6, Gongdong 2nd Road, Quanxing Industrial Park, Shengang Township, Changhua County

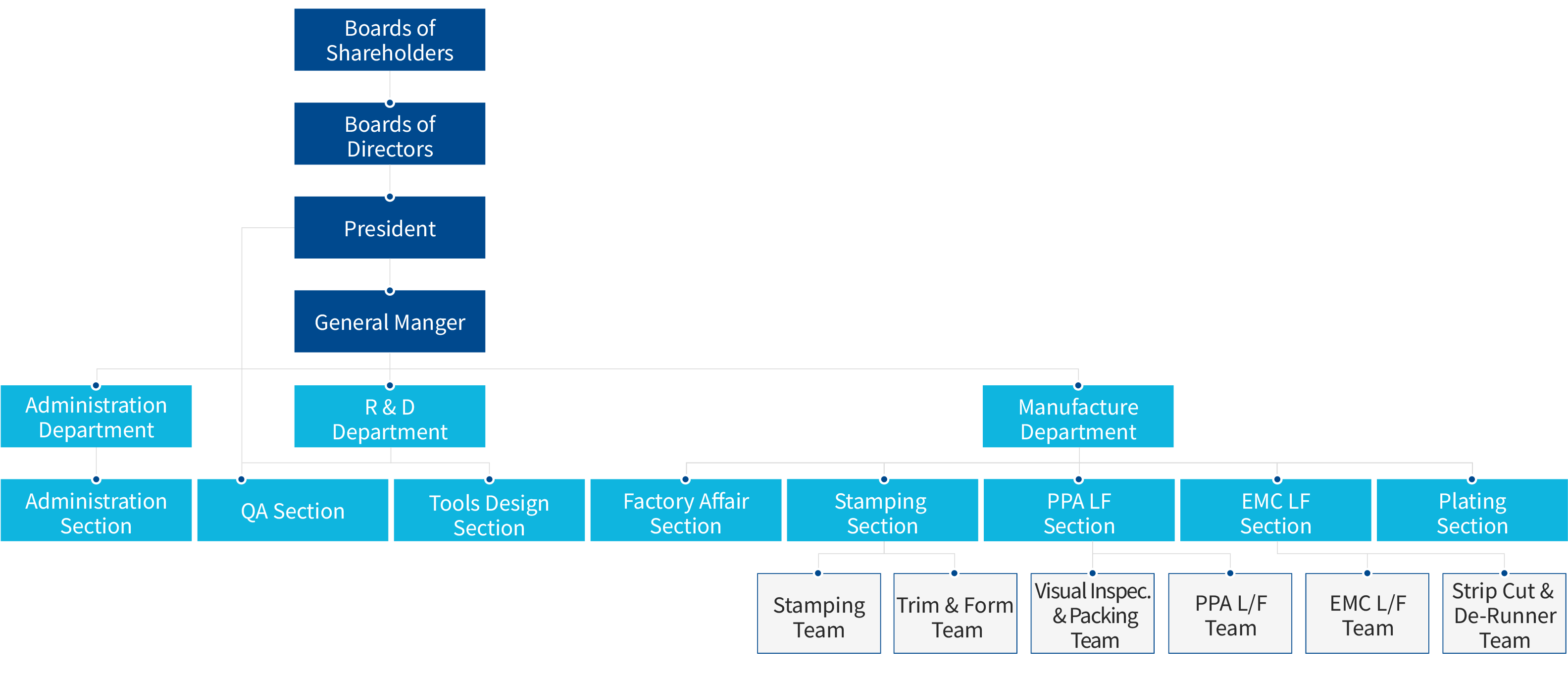

Company Organization

History

2007

07月

2007

09月

2007

12月

2008

06月

2008

07月

2008

10月

2009

08月

2010

07月

2011

03月

2012

08月

2012

10月

2013

07月

2013

09月

2013

10月

2016

05月

2017

01月

2017

12月

2018

01月

2021

07月

2022

01月

2022

06月

2024

05月

2025

05月

2025

07月

2025

07月

- ttop corp. was established to specialize in the design, manufacturing, and production of precision progressive dies and precision insert molding.

- The company is located in Hemei Township, Changhua County, leasing a facility of approximately 90 ping (about 300 square meters), dedicated to new product development, trial production, and formulation of company management policies.

- The progressive die for the 27x27 BGA heatsink has been built-up and start to mass production.

- The insert molded lead frame for Side-View SMD-LED, 0.6mm height, 020 type with 4 rows, has been built-up and start to mass production..

- We have relocated to our newly built, self-owned factory in Quanxing Industrial Park, Changhua County.

- The progressive die for semiconductor SMB lead frame (6x2) and clip (4x3) have been built-up and start to mass production.

- The first-generation high-density multi-row PPA SMD-LED lead frame(384Pcs/Frame) has been successfully developed and in mass production.

- The company has been certified for ISO 9001:2000 by TÜV Rheinland Taiwan.

- The insert Mold for Side-View 0.4T SMD LED L/F has been build-up and this mold has a monthly production capacity of over 6 million pieces (6KK pcs).

- The second-generation high-density multi-row PPA SMD-LED lead frame (448Pcs/Frame)has been successfully developed and entered mass production.

- The company has been certified by TÜV Nord Taiwan for compliance with the ISO 14000 Environmental Management System.

- The factory expansion has been completed, and monthly shipments of SMD-LED lead frames have surpassed 500 million pieces (500 KKPcs).

- The third-generation high-density multi-row PPA SMD-LED lead frame (512Pcs/Frame)has been successfully developed and entered mass production.

- The third-generation high-density multi-row PPA SMD-LED lead frame (768Pcs/Frame)has been successfully developed and entered mass production.

- The first individual type SMC-LED lead frame (clamp test type) tools has developed and trial mass production.

- The company has been certified by TÜV Nord Taiwan for compliance with the TS16949 Quality Assurance System.

- Commencement of delivery for Ni-Pd-Au plated PPA LED lead frames used in automotive applications.

- Start to offer Ni-Pd-Au plated EMC LED lead frames for automotive applications has commenced.

- The company has been certified by TÜV Nord Taiwan for compliance with the IATF 16949:2016 Quality Management System.

- The first individual type EMC & SMC LED lead frame (bottom test type) tools has developed and trial mass production.

- The first 75mm wide individual type bottom test EMC 3030 (2.4 cup) LED lead frame has been successfully developed and mass production.

- Many models of the 75mm wide individual type bottom test EMC LED lead frames has been successfully developed and mass production.

- The first Insert Molding Parts for reflective sensor was start to mass production.

- The first Transfer Molding Parts for medical device was start to mass production.

- The first Insert Molding Parts for filter device was start to mass production.

- The individual type EMC LED L/F had shipped more than 25,000 KKPcs

- The EMC LED L/F with Ni-Pd-Au Plated had shipped more than 480 KKPcs.

Quality Certification