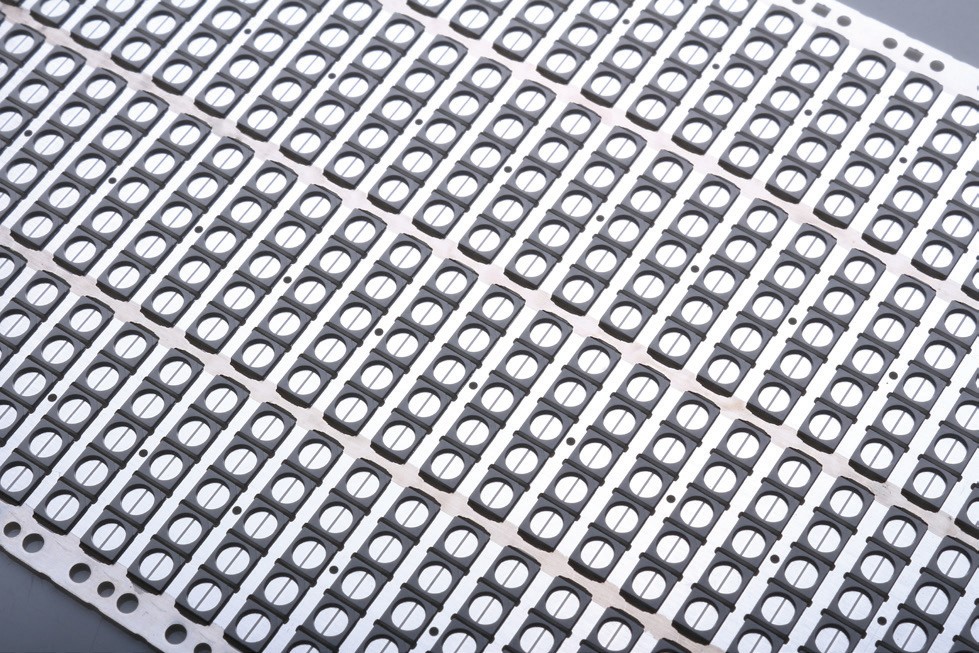

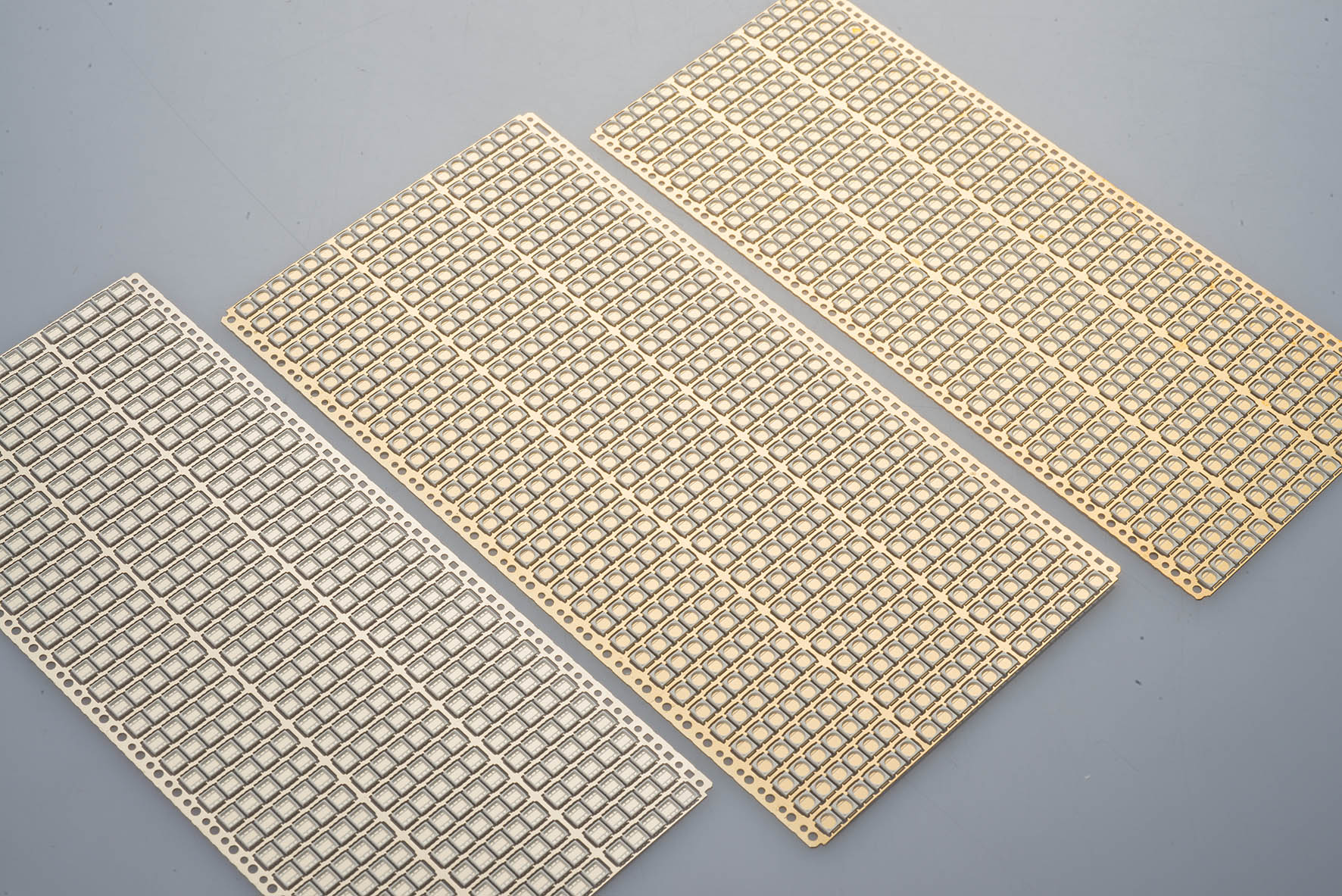

Transfer Molding Parts for Various Components

Transfer Molding Parts for Various Components

These components are specifically designed for various parts and are produced through a process called transfer molding, where metal inserts are embedded into thermosetting parts. The goal is to enhance the performance, durability, and functionality of the final products, making them widely applicable across different industries.

Applications:

Electronic Components:

Used in electronic devices for components such as LEDs, connectors, switches, and brackets, providing necessary strength and functionality.

Automotive Parts:

Applied in automotive components like LED ambient lights, fasteners, and connectors to improve durability and performance in vehicles.

Medical Devices:

Used in parts of medical instruments, such as sensors and diagnostic equipment, requiring high precision and reliability.

Consumer Electronics:

Found in components for consumer electronic products such as mobile phones, computers, and household appliances, offering structural support and functional integration.

Advantages:

Enhanced Strength and Durability:

Metal inserts improve the overall strength and durability of the components, making them suitable for high-stress and demanding environments.

Functional Integration:

Allows multiple functions to be integrated into a single component, reducing the need for additional parts and assembly steps.

Design Flexibility:

Injection molding enables the creation of complex shapes and precise dimensions, meeting diverse product design requirements.

Cost Efficiency:

By combining metal and plastic in a single component, manufacturing costs are reduced and the production process is simplified.