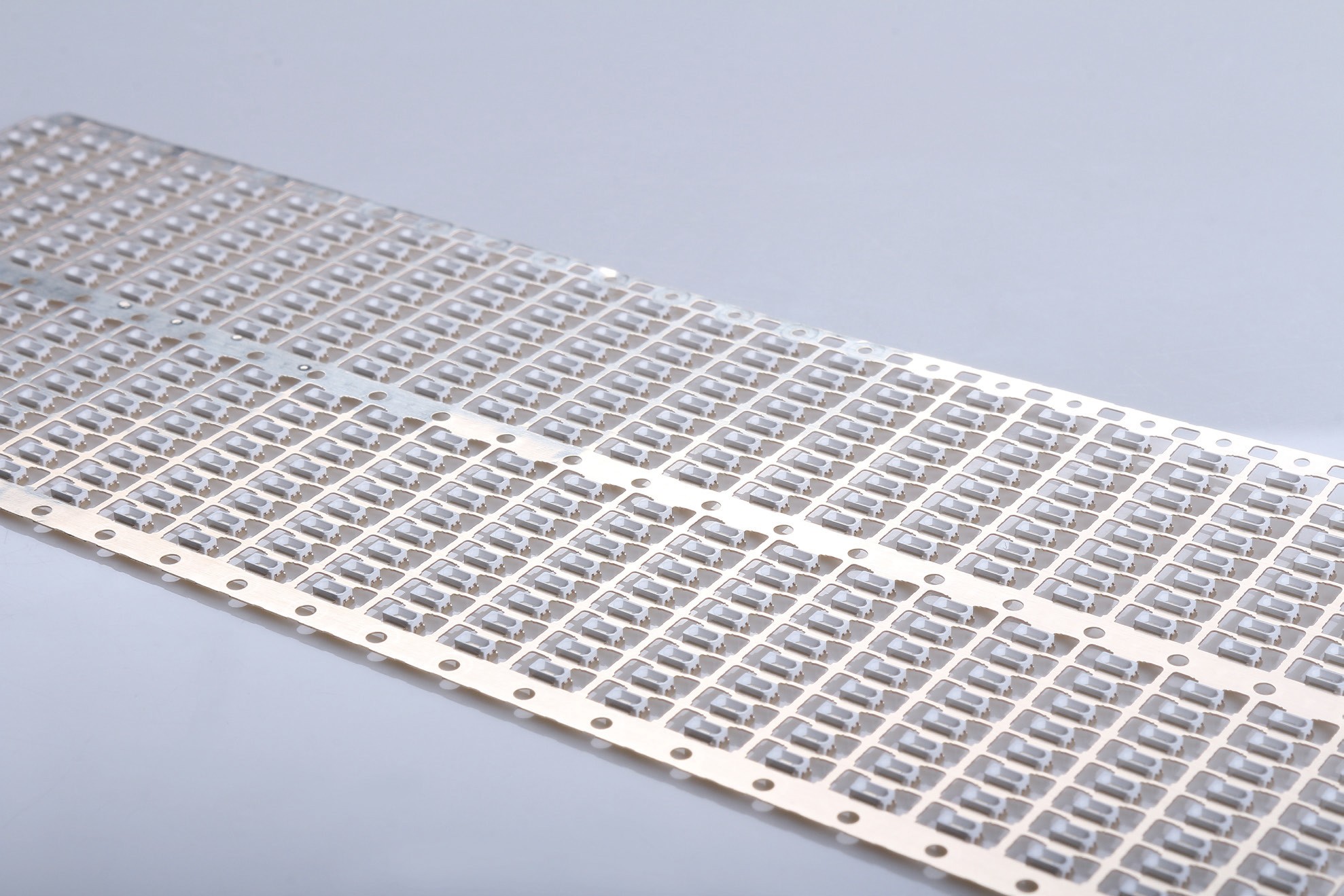

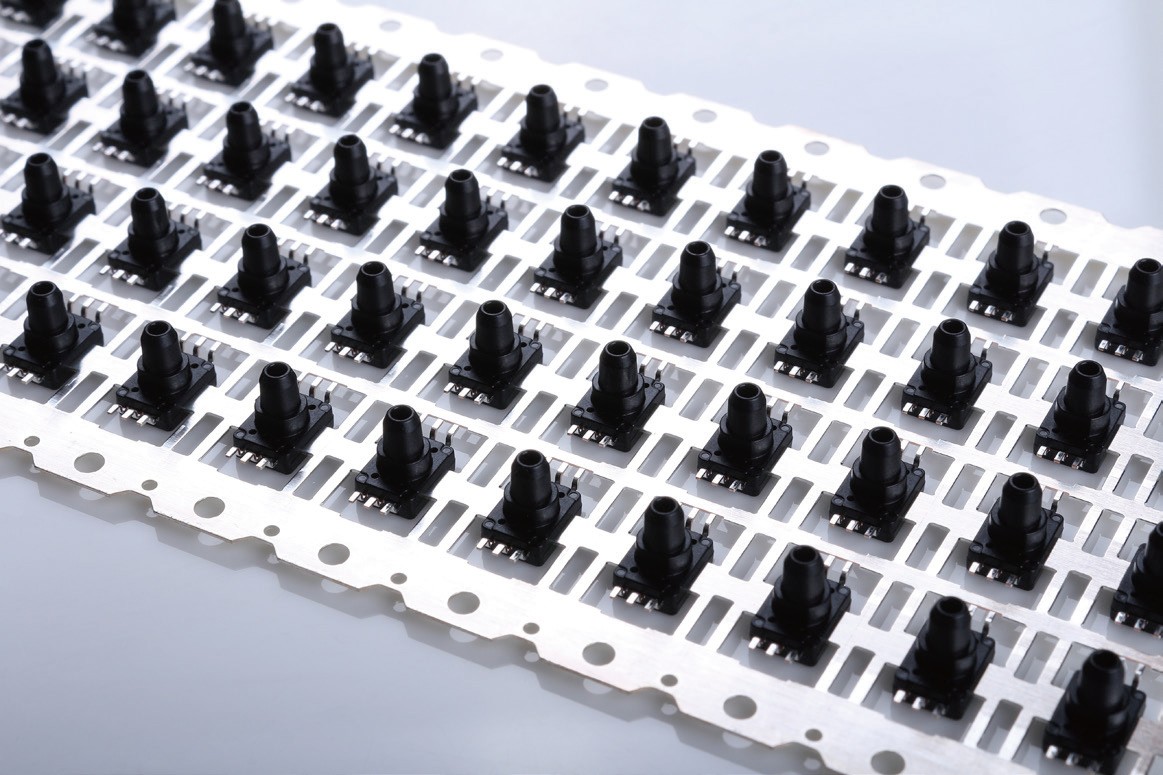

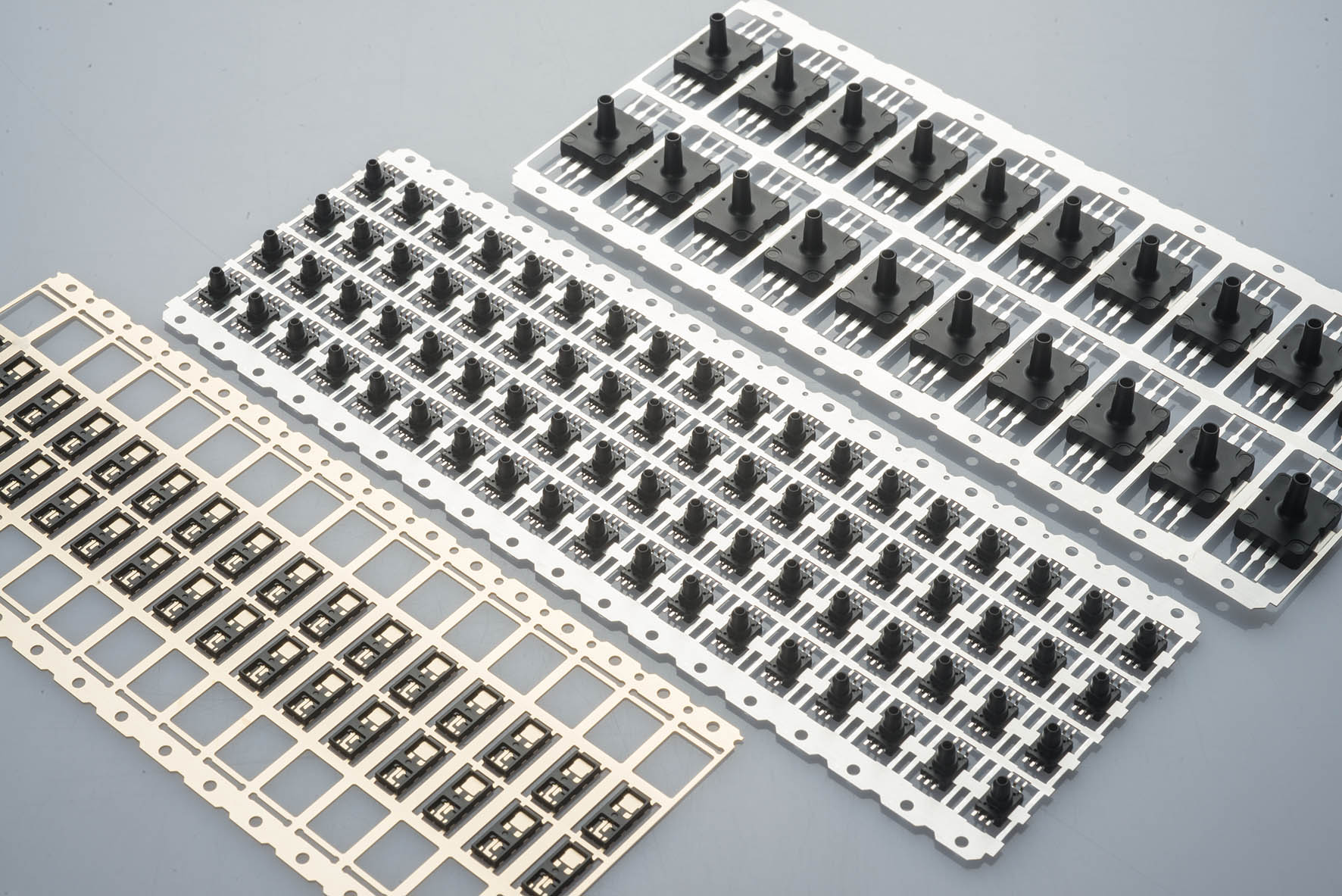

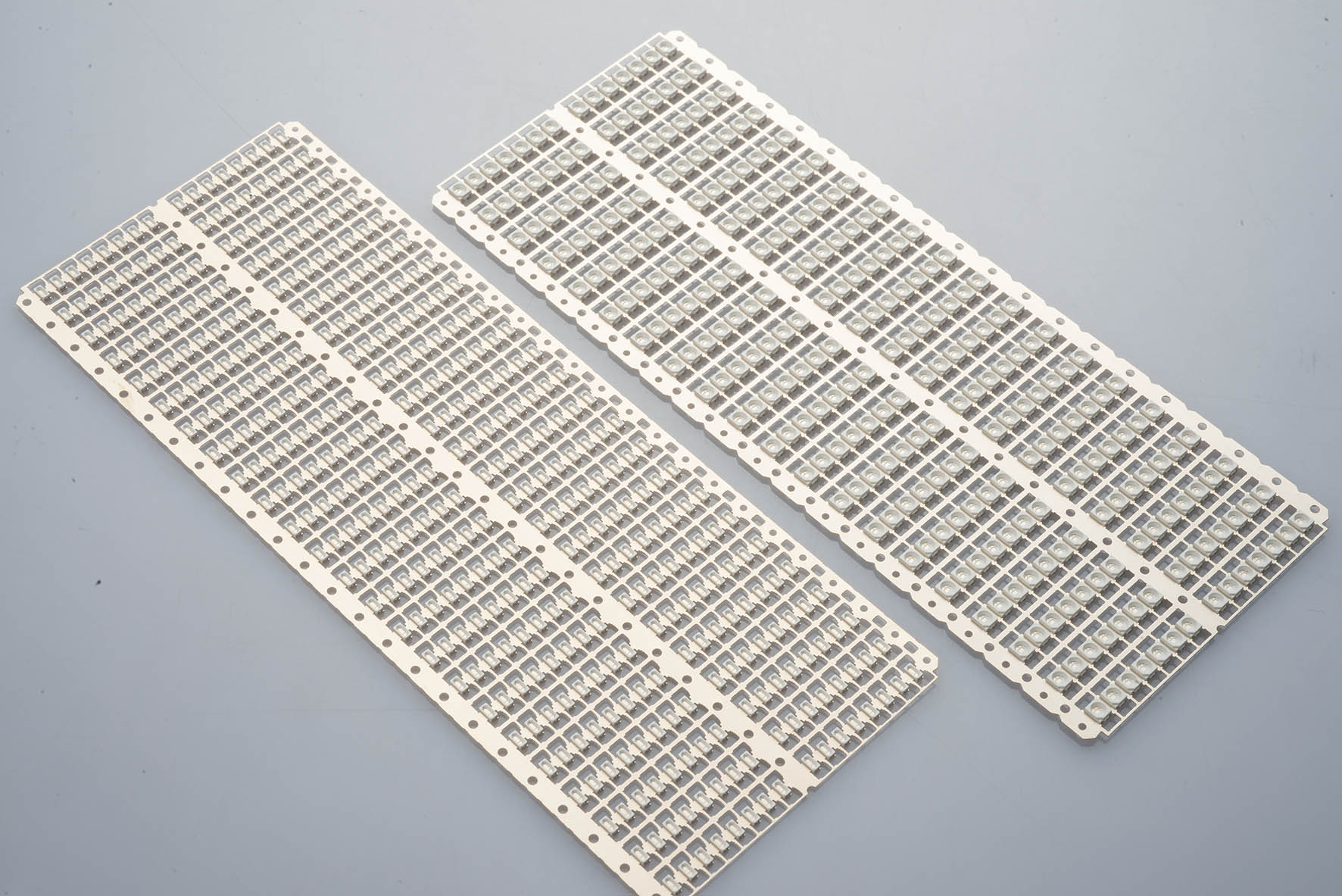

Insert Molded Parts for Veriety Component

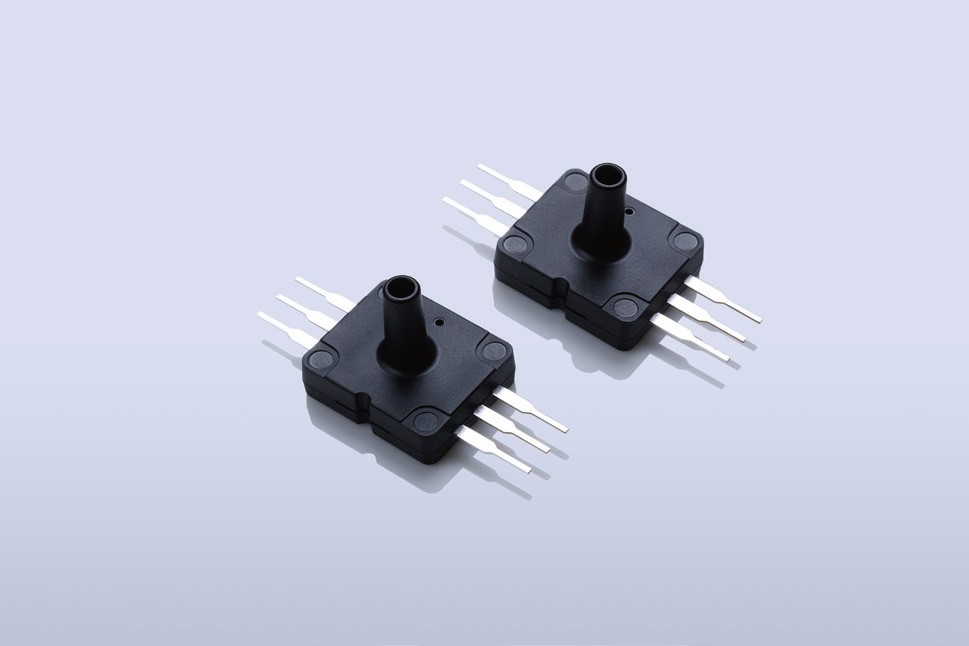

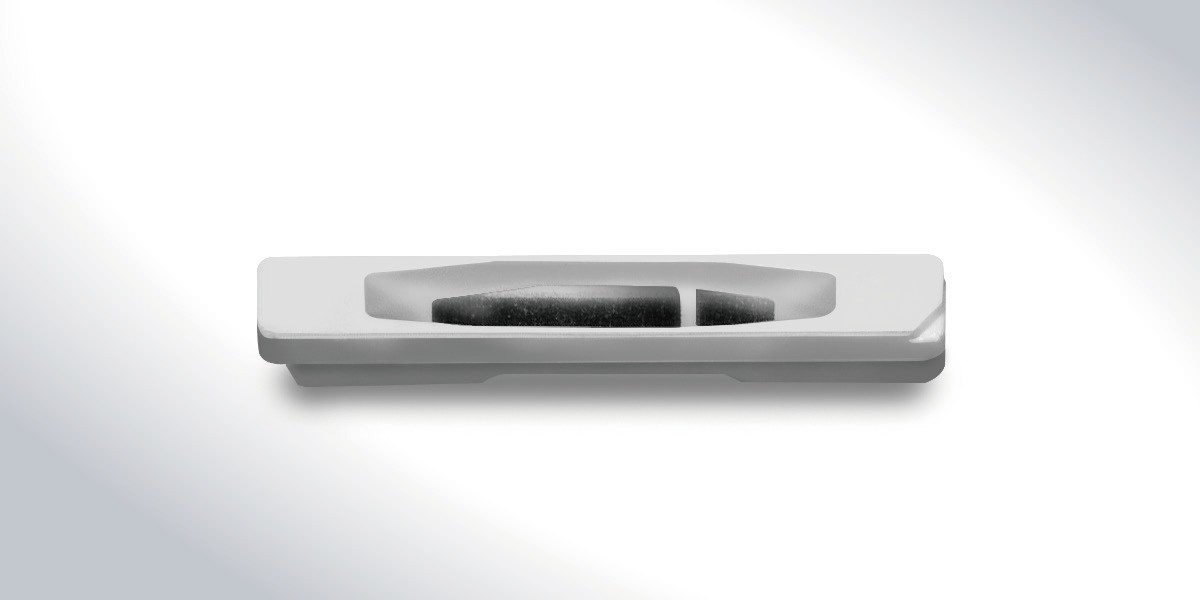

Insert molded parts for various components are specialized components designed by embedding metal or other materials into plastic parts through the insert molding process. These parts are used in a wide range of applications across different industries, combining the benefits of both metal and plastic to meet specific functional requirements.

Applications:

Automotive Components: Used in various automotive parts such as brackets, connectors, and fasteners, where enhanced strength and functionality are required.

Consumer Electronics: Applied in electronic devices like smartphones, tablets, and wearables, where high mechanical strength and electrical performance are needed.

Industrial Machinery: Utilized in machinery components that require durable and reliable parts, including control panels and structural elements.

Medical Devices: Employed in medical equipment and devices, where precision, reliability, and strength are critical for safe and effective operation.

Aerospace Components: Used in aerospace applications for parts that require high strength-to-weight ratios and precision, such as structural components and connectors.

Advantages:

Enhanced Performance: Combining metal inserts with plastic provides improved strength, durability, and functionality compared to using plastic alone.

Design Flexibility: Injection molding allows for the creation of complex shapes and precise dimensions, meeting specific design requirements.

Cost-Effectiveness: Insert molding can reduce manufacturing costs by integrating multiple functions into a single part and streamlining the production process.