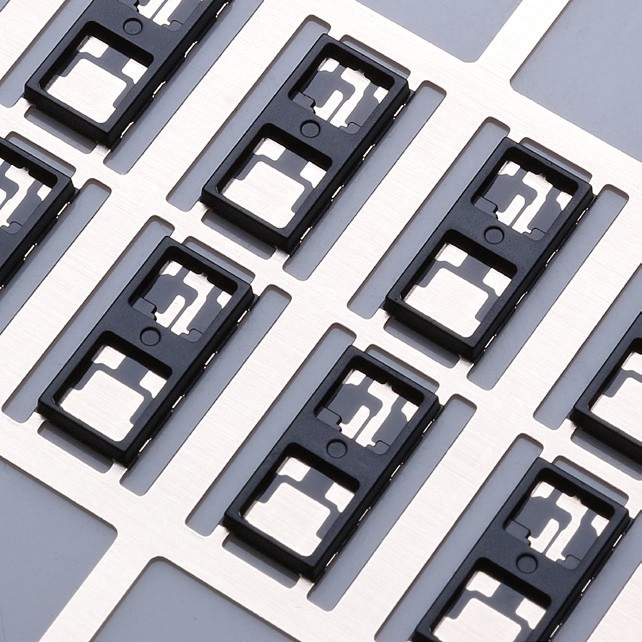

Insert Molded Parts for Vehicles

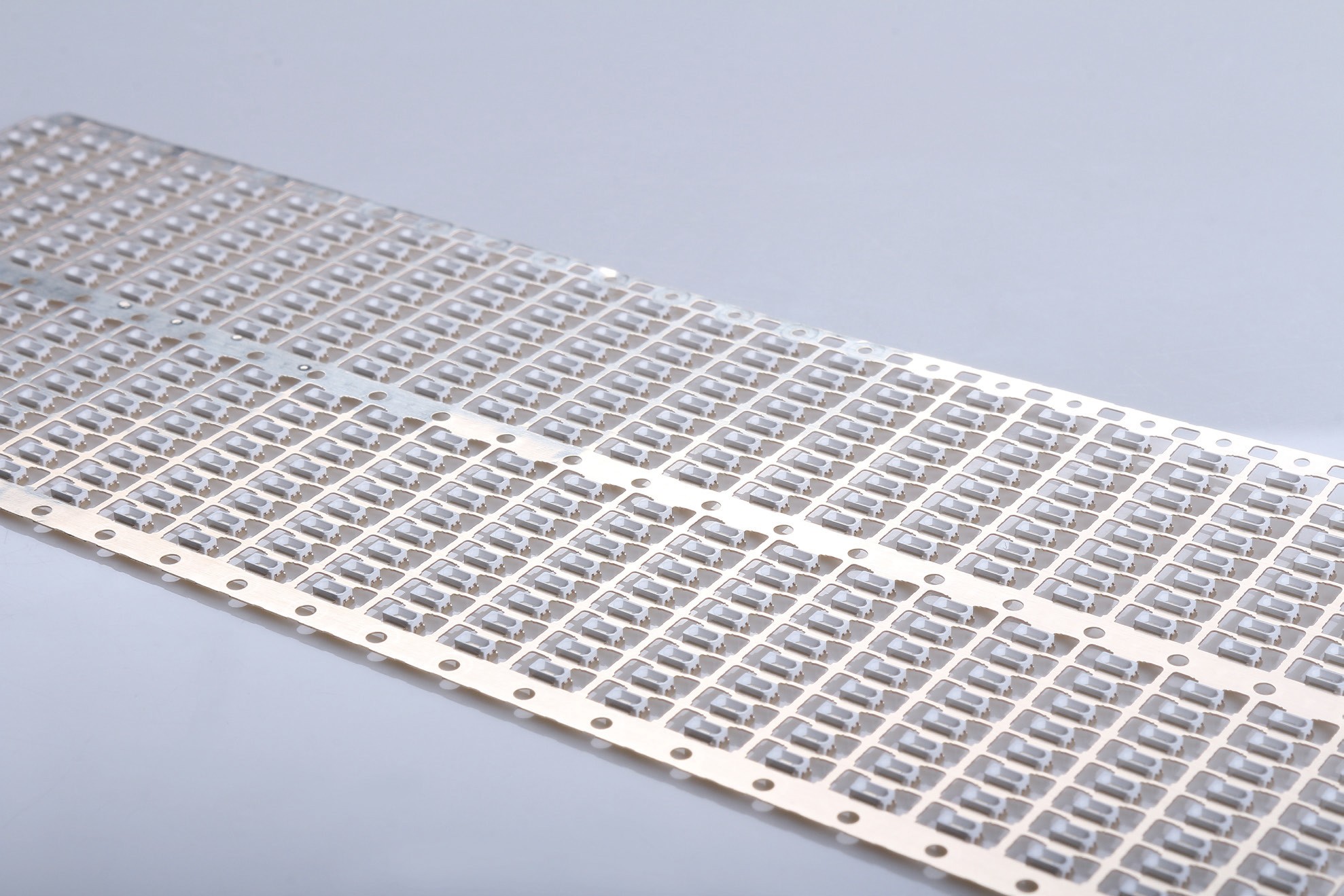

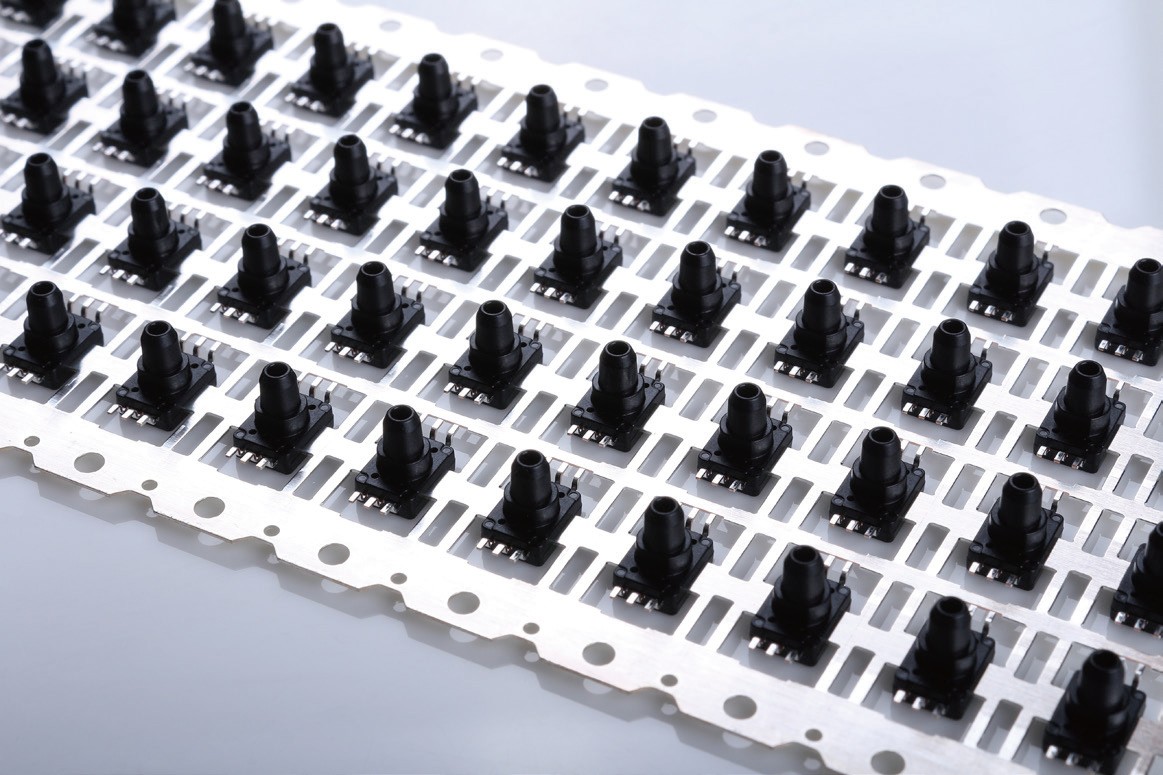

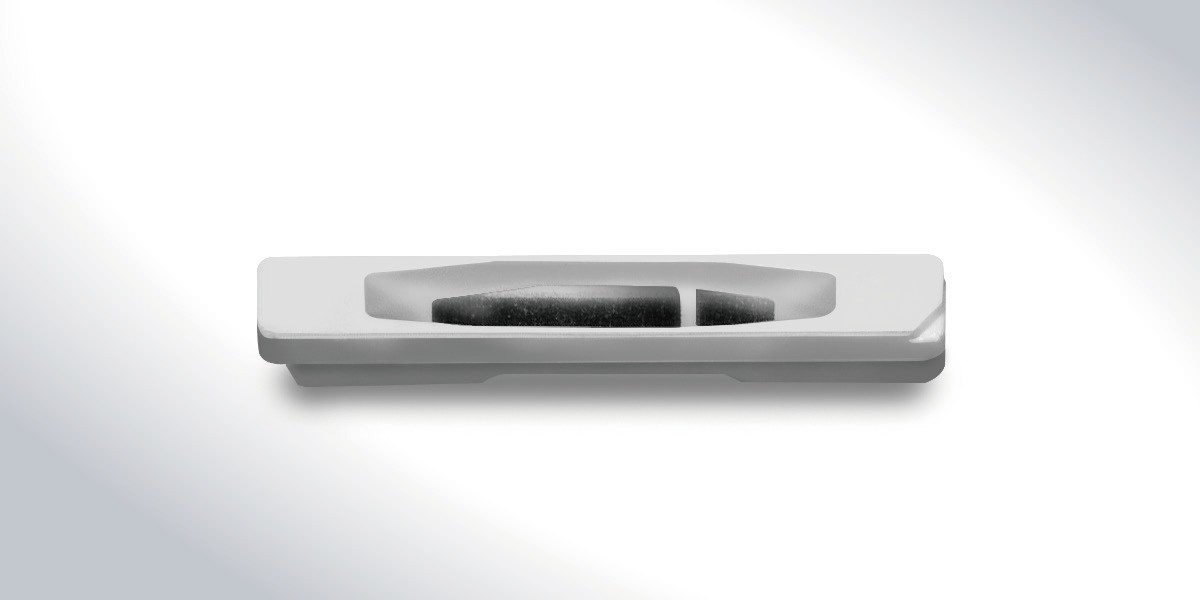

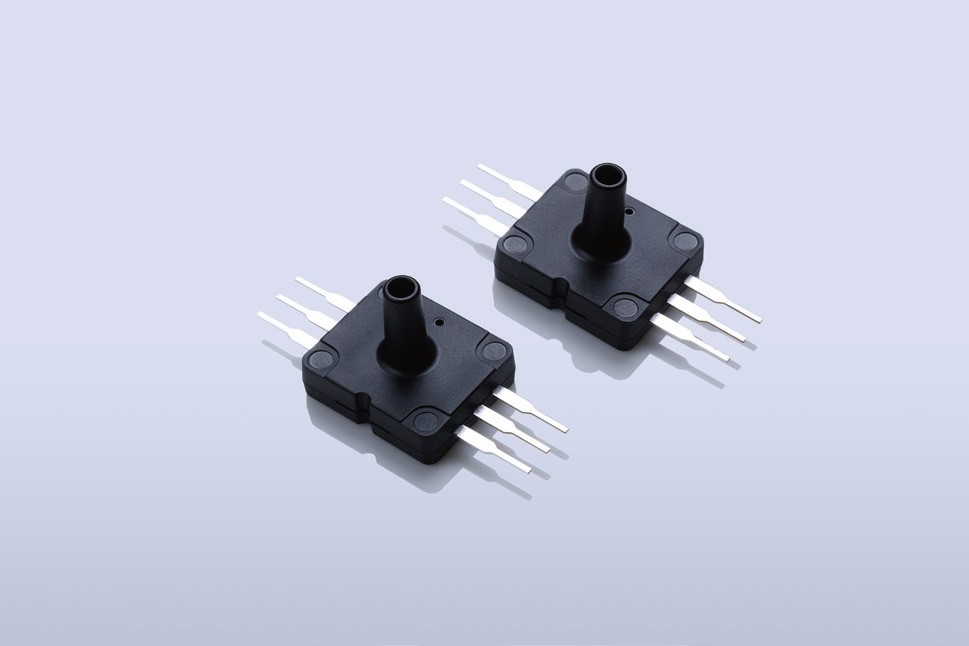

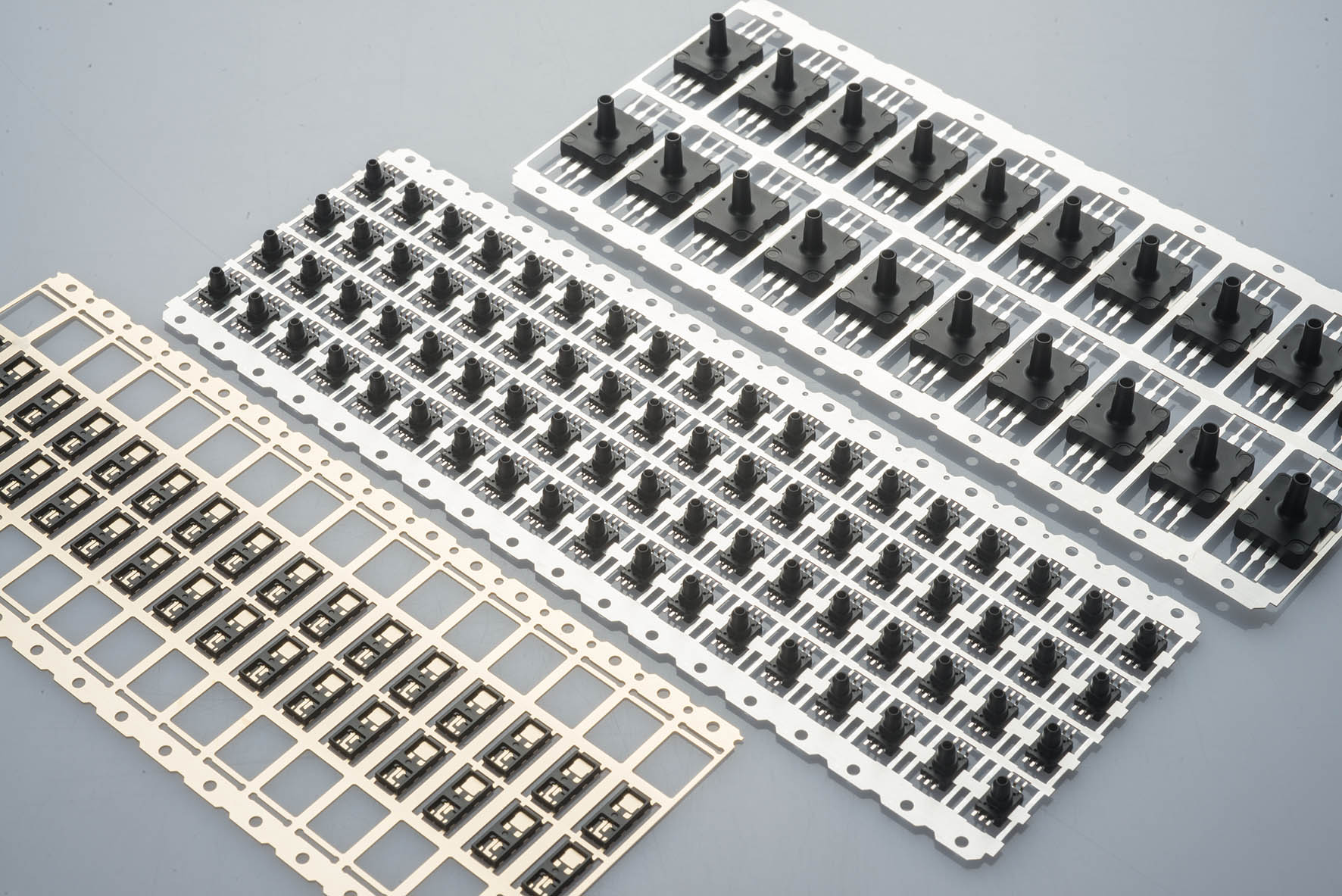

Insert molded parts for vehicles involve embedding metal or other materials into plastic components using insert molding technology. These parts are designed to enhance the performance, durability, and functionality of various vehicle components.

Applications:

Automotive Components: Used in parts such as brackets, connectors, and mounting elements that require enhanced strength and durability for various vehicle systems.

Engine Parts: Applied in components like engine mounts and supports, where both strength and precision are critical for performance.

Interior Components: Utilized in vehicle interiors for parts like control panels and trim pieces that benefit from the combination of strength and aesthetic flexibility.

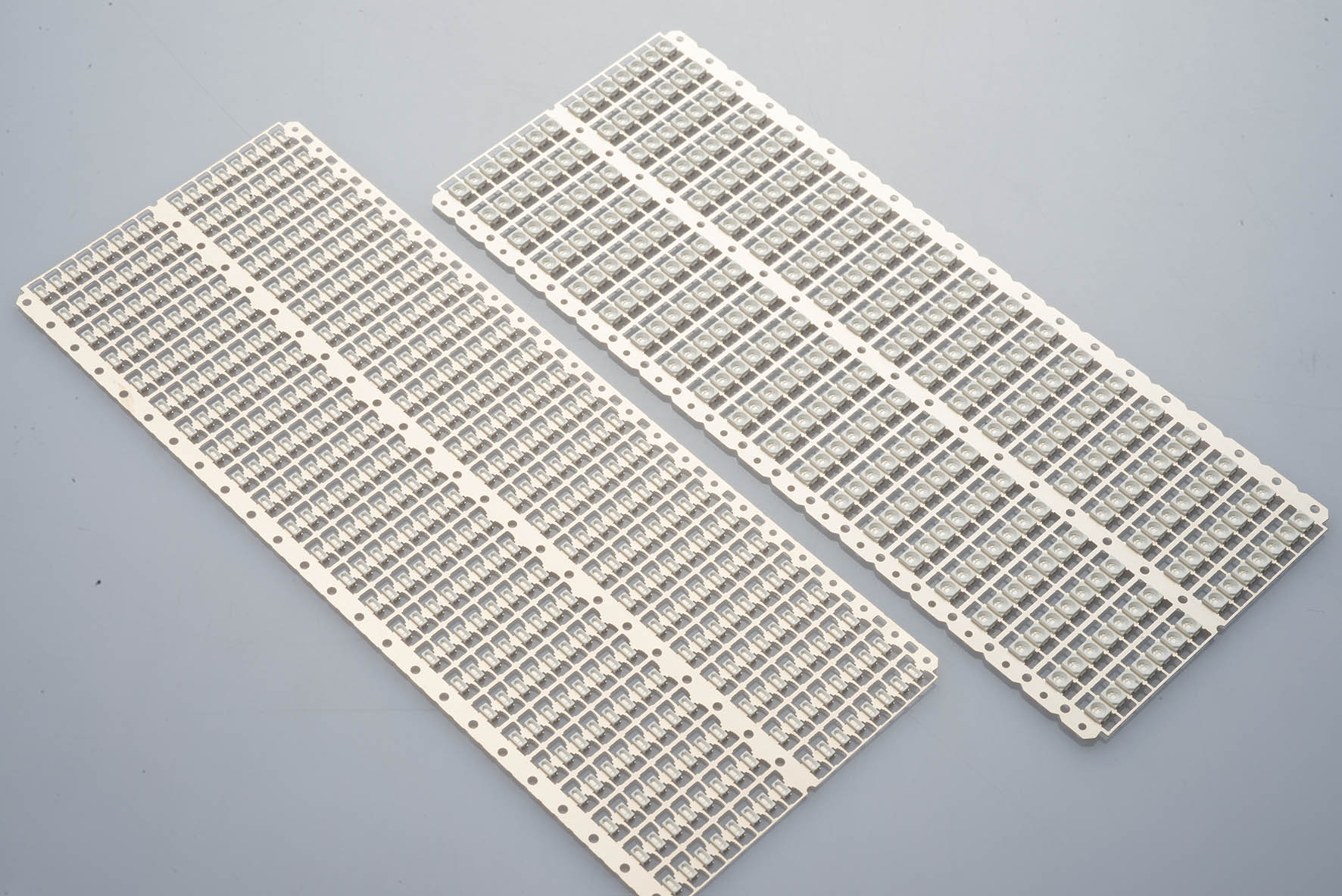

Electrical Systems: Employed in connectors and housings for electrical systems, providing reliable electrical connections and protection.

Safety Features: Used in safety-related parts such as airbags and seatbelt components, where strength and reliability are paramount.

Advantages:

Enhanced Strength and Durability: The metal inserts increase the overall strength and durability of the parts, making them suitable for high-stress applications in vehicles.

Functional Integration: Allows for the integration of multiple functions into a single part, reducing the need for additional components and assembly steps.

Design Flexibility: Injection molding enables the creation of complex shapes and precise dimensions, accommodating various design requirements for vehicle components.

Cost Efficiency: By combining metal and plastic in a single part, insert molding can reduce manufacturing costs and streamline the production process.