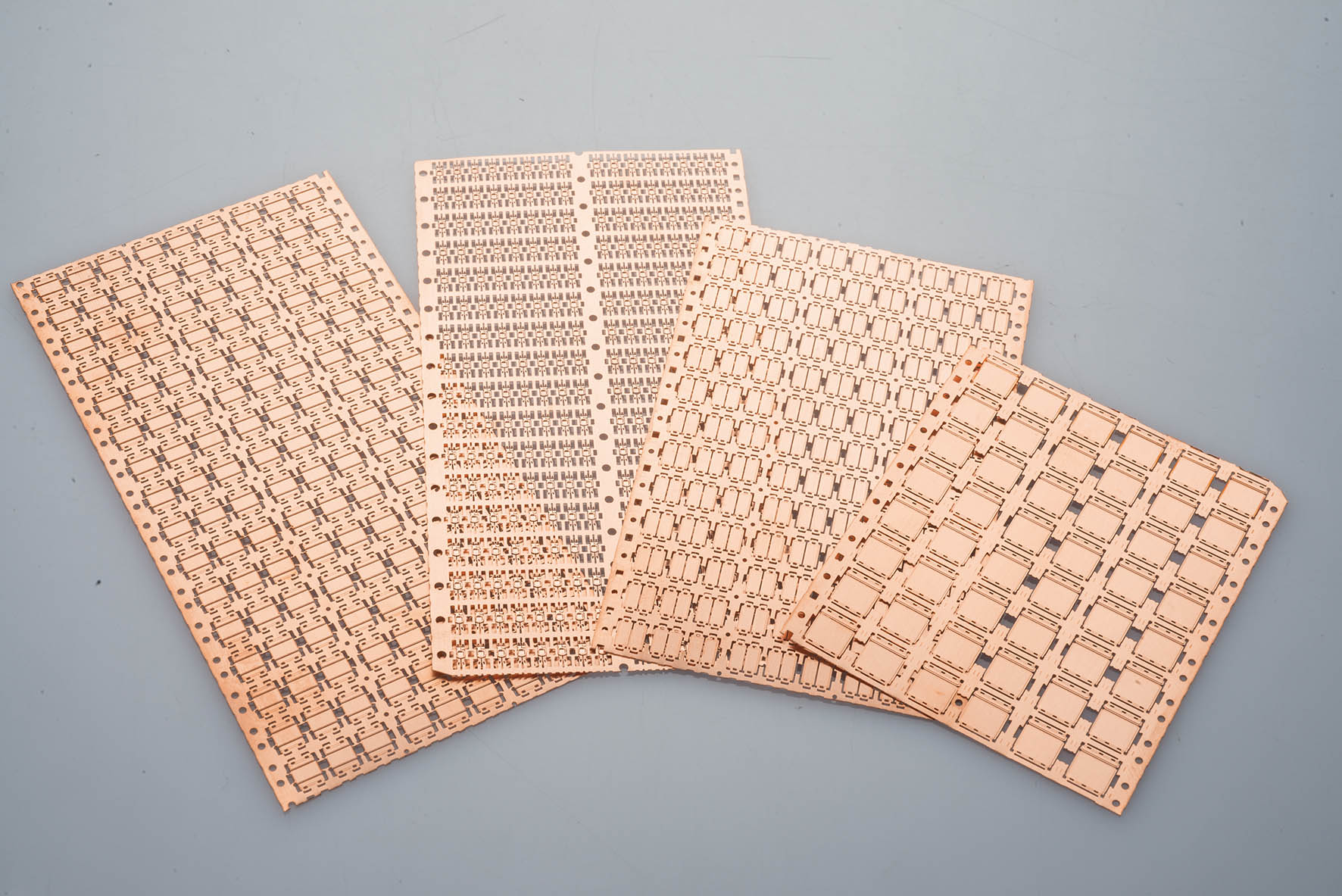

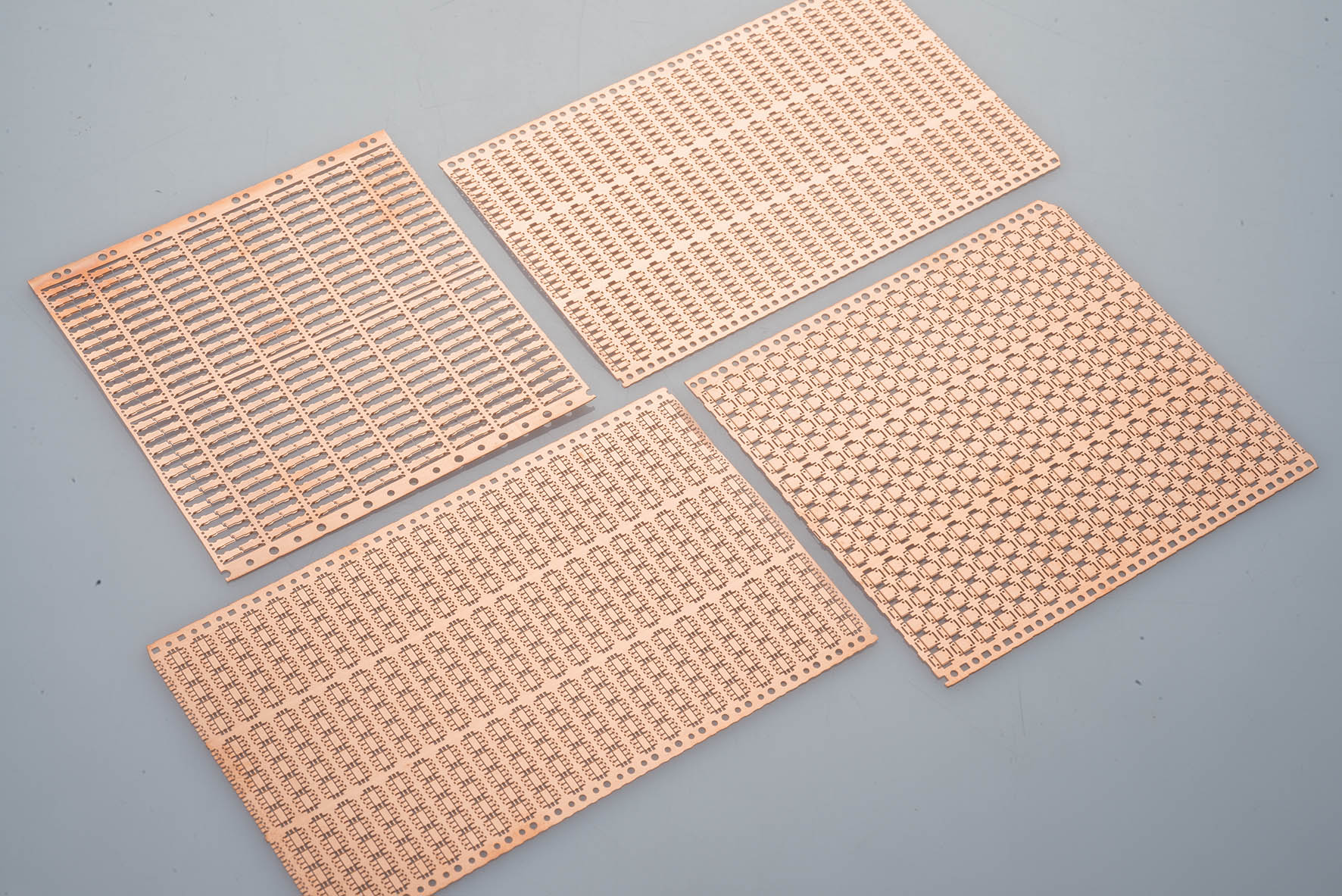

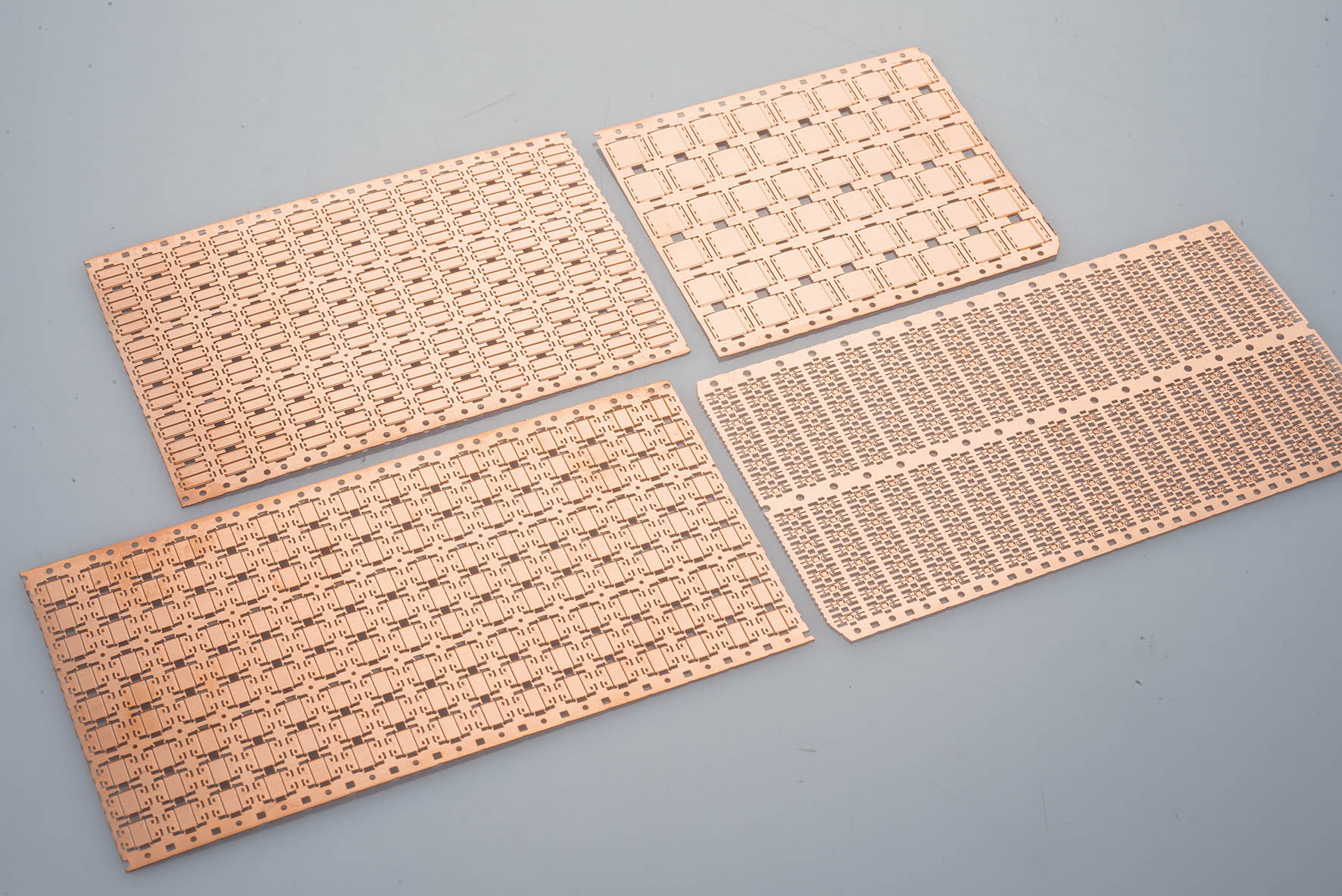

Lead Frame for LED

Lead Frame for LED

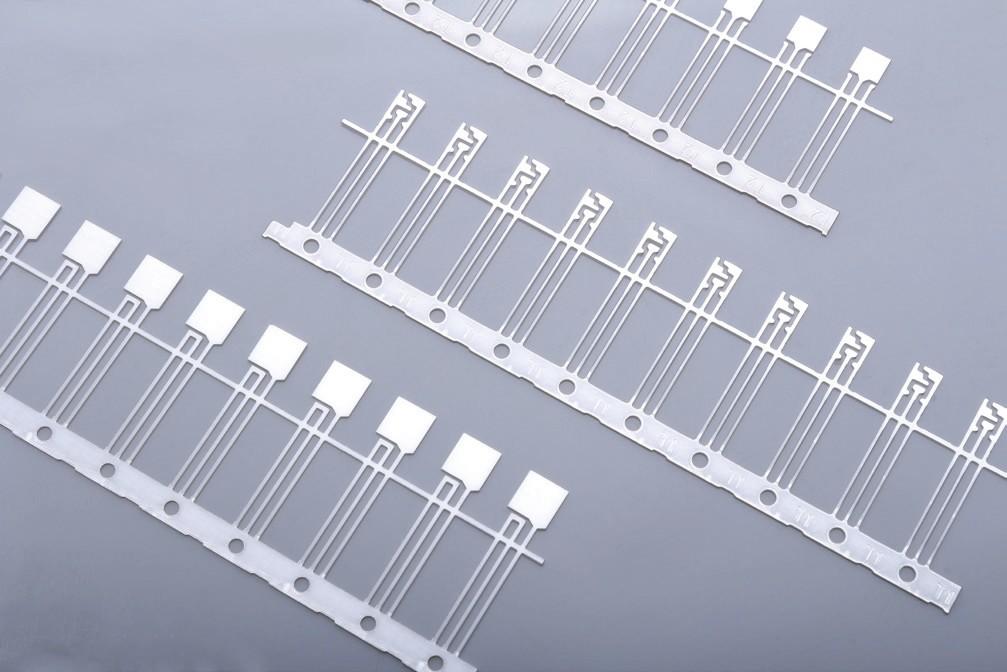

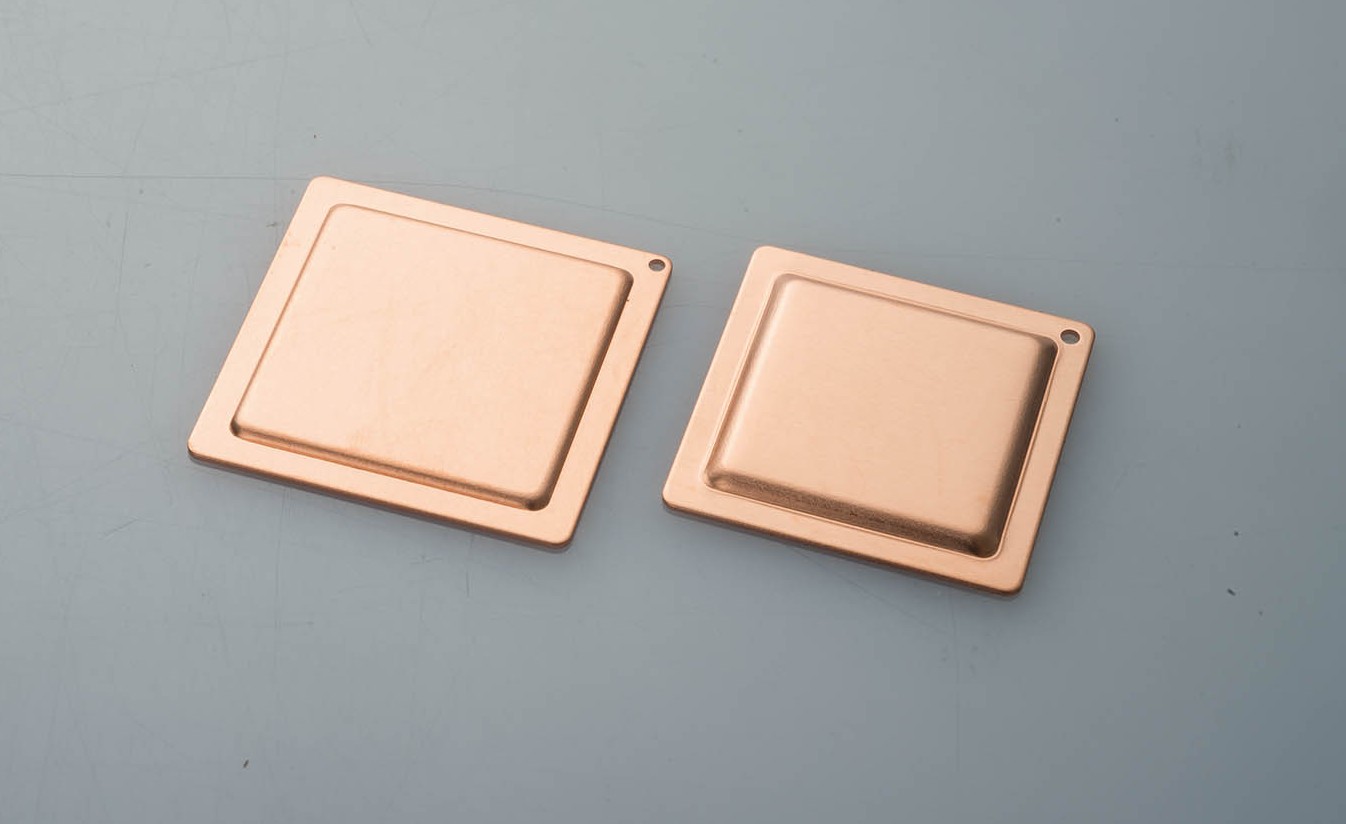

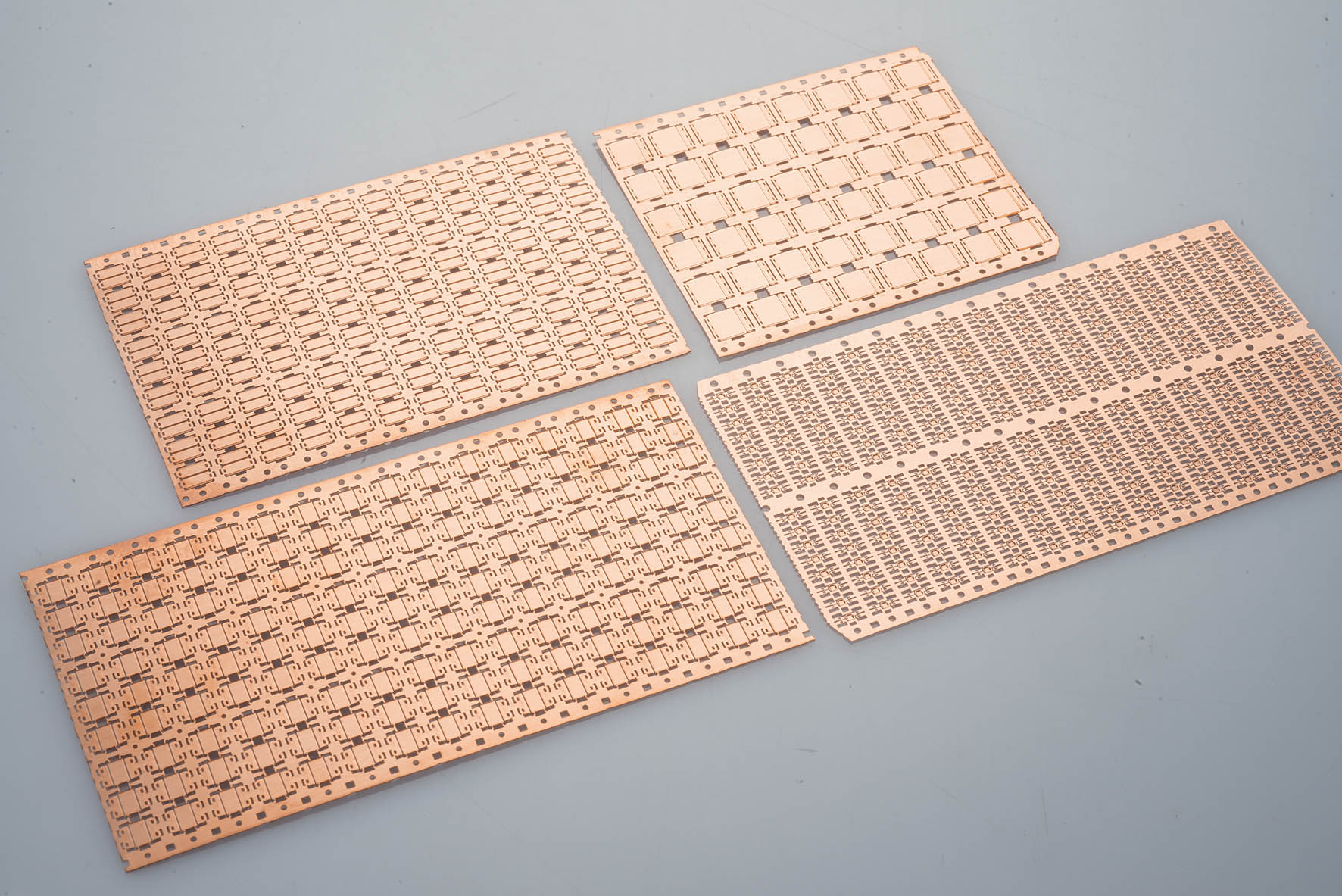

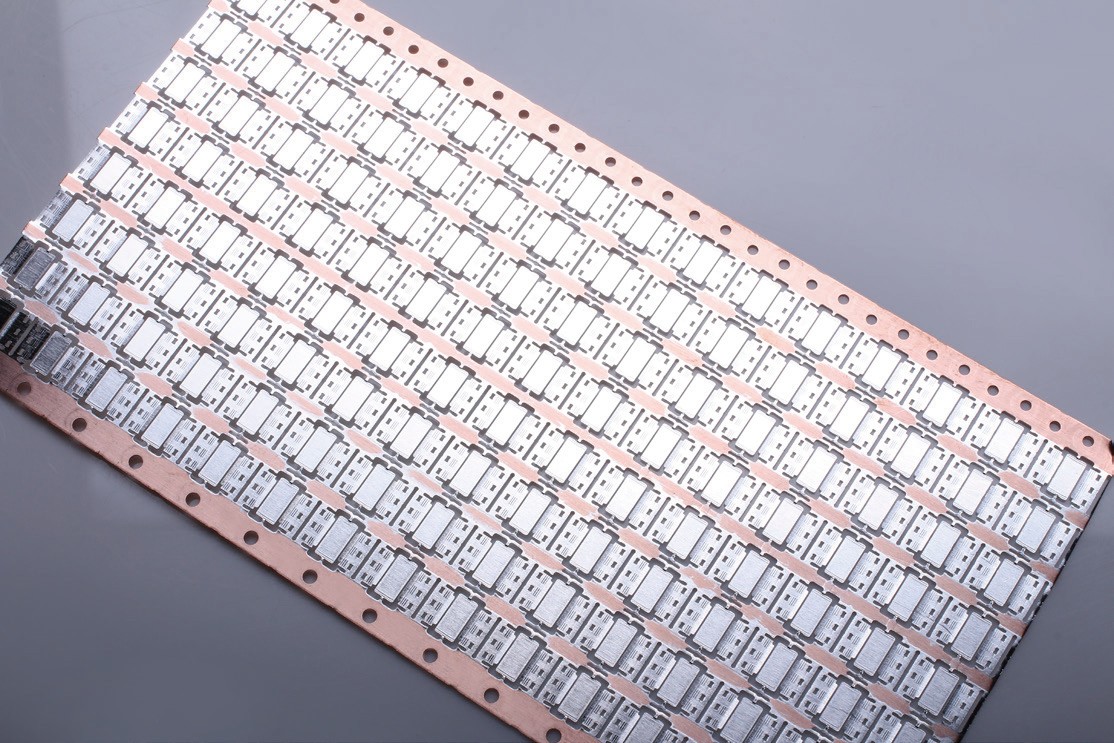

LED lead frames are essential components used in the manufacturing of LED (Light Emitting Diode) products. These L/F play a crucial role in providing structural support, electrical connectivity, and thermal management for LED chips.

Key Functions:

Structural Support: LED lead frames offer mechanical stability to the LED chip, ensuring it remains securely in place within the package.

Electrical Connectivity: They provide pathways for electrical connections between the LED chip and external circuits, enabling efficient power and signal transmission.

Thermal Management: The lead frames help dissipate heat generated by the LED chip during operation, maintaining optimal performance and extending the lifespan of the LED.

Manufacturing Process:

Design: The design of the lead frame is tailored to the specific requirements of the LED chip, taking into account factors such as size, shape, and electrical characteristics.

Stamping: Metal coils, often made from copper or alloys, are stamped into the desired shape using precision progressive die.

Plating: The lead frames are plated with materials like Ag , Ni-Pd-Au or Ni-Au to enhance their electrical conductivity and corrosion resistance.

Forming: The lead frames are subjected to further processes such as Forming and Trimming to achieve the final required shape.

Applications:

LED lead frames are used in a wide array of LED products, including general Lighting , Back Light, automotive lights, and electronic devices. As the demand for LED technology grows, lead frame designs continue to evolve to enhance efficiency, performance, and cost-effectiveness.